Profili metallici su misura

Profili speciali su misura in acciaio e alluminio profilati a freddo

Sika profili metallici

In Sika Profili siamo specializzati nella produzione di profili metallici su misura a disegno di alta qualità mediante profilatura a freddo. Sono realizzati con tecnologie all’avanguardia e materiali come l’acciaio inox, l’acciaio zincato, l’acciaio decappato, l’acciaio corten, l’alluminio e il rame.

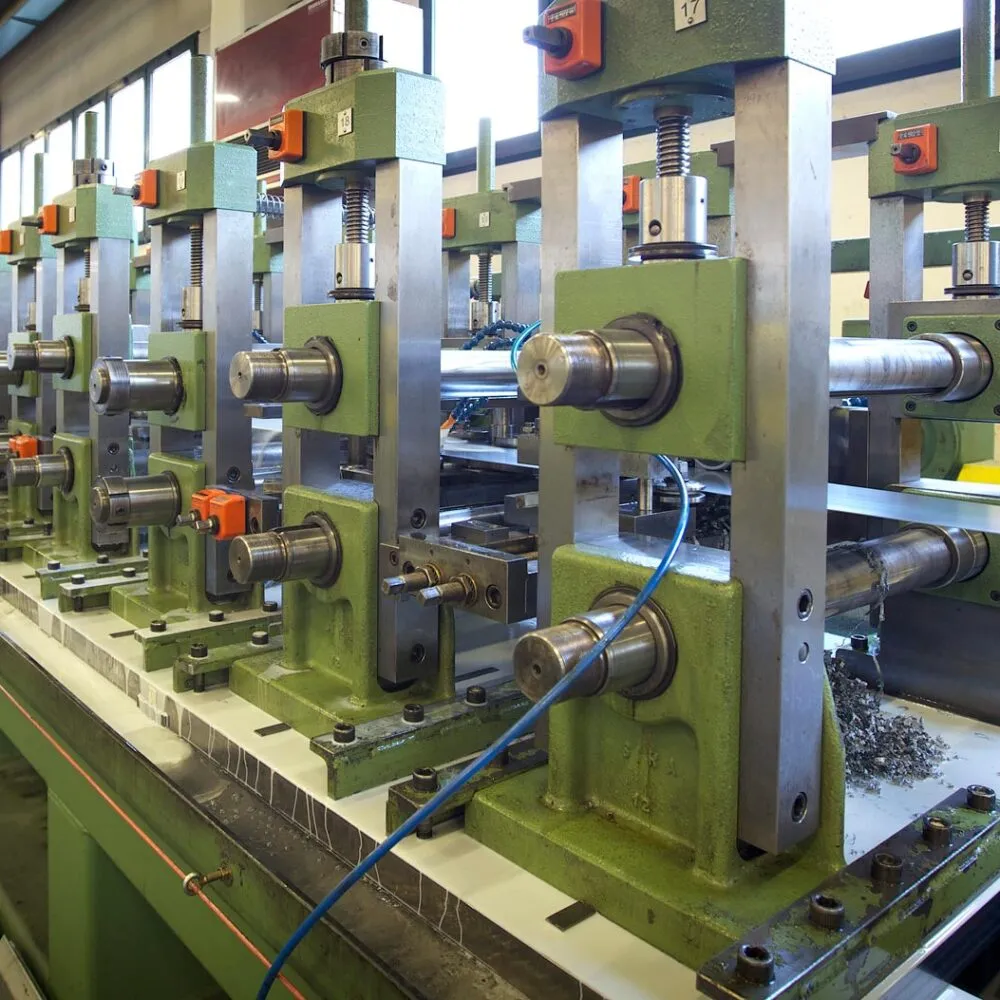

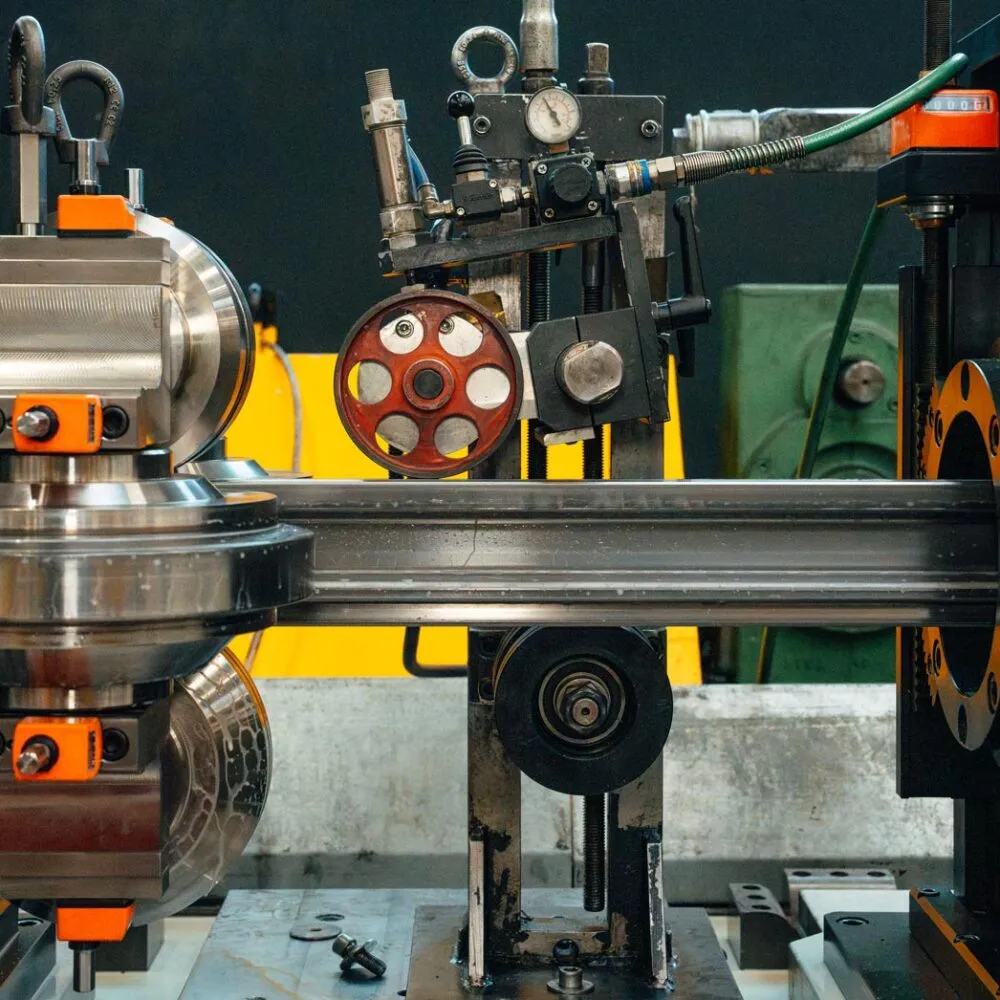

Siamo specializzati nella profilatura a freddo e a rulli, oltre che nello stampaggio a freddo, fornendo profilati speciali in acciaio per numerosi settori industriali. Azienda giovane e dinamica con esperienza pluridecennale, mettiamo a disposizione competenze avanzate nella lavorazione del metallo e nella realizzazione di profili in acciaio personalizzati, garantendo soluzioni robuste, affidabili e su misura per clienti in tutto il mondo.

Lavorazioni su misura

Realizziamo profili su misura attraverso lavorazioni metalliche per mezzo della profilatura a freddo, lo stampaggio a freddo, la curvatura, la calandratura e saldatura HF.

Lavorazioni su misura

Campi di applicazione

I nostri profili speciali su misura trovano impiego in svariati settori industriali: dall’edilizia alle infrastrutture, dall’automotive all’arredamento, dalle energie rinnovabili ai sistemi di parcheggio, fino ad arrivare all’industria e all’agricoltura con i pali per vigneto.

La nostra consolidata esperienza, l’innovazione continua e la solidità nel settore ci rendono il partner ideale per chi cerca soluzioni di alto livello. Affidarsi a Sika per la produzioni di profili metallici su misura significa scegliere un’azienda con elevati standard qualitativi. Scopri le certificazioni ottenute a conferma del nostro impegno.

Materiali lavorati

Scopri i materiali lavorati a freddo da coils: acciaio inox, decappato, corten, zincato, alluminio e rame. Trasformiamo bobine di lamiera in profilati metallici su misura di alta qualità che rispondono alle esigenze e applicazioni più diverse dei nostri clienti.

Resta aggiornato sulle nostre news di settore, appuntamenti e aggiornamenti

Pali per vigneto in acciaio

I pali in acciaio corten e zincato Sika garantiscono massima resistenza e durata! Con oltre 400 mila pali consegnati ogni anno, siamo i “sarti dell’acciaio” per il tuo vigneto. Scarica il nostro catalogo prodotti e contattaci per un preventivo gratuito e senza impegno.

Profili metallici speciali su misura profilati a freddo

Realizziamo profili speciali su misura profilati a freddo in acciaio e alluminio. Lavoriamo diverse tipologie di metalli, come l’acciaio inox, l’acciaio zincato, l’acciaio decappato e Corten, assicurando massima versatilità di impiego. Grazie a macchinari e tecnologie all’avanguardia di profilatura a freddo e stampaggio, forniamo soluzioni affidabili per settori che spaziano dall’edilizia all’automotive. I processi tecnologicamente avanzati, come punzonatura automatizzata, stampaggio, calandratura e saldatura HF, garantiscono precisione, resistenza e flessibilità. La qualità certificata e la personalizzazione su disegno completano l’offerta, rendendo Sika un partner ideale in ambito industriale e per progetti custom in tutto il mondo.

Leggi di più

Lavorazioni tecniche su profili metallici

L’intero processo di lavorazione è eseguito internamente e include stampaggio a freddo, punzonatura lamiera, curvatura profili metallici, calandratura profili metallici, saldatura HF, taglio a misura e giunzione profili. Grazie a queste tecnologie possiamo realizzare profili forati, sagomati, curvati o assemblati per l’integrazione in sistemi modulari e strutture tecniche.

Materiali lavorati: acciai e leghe speciali

Sika lavora una vasta gamma di materiali: profili acciaio zincato, profili in acciaio inox, profili acciaio corten, acciaio carbonio, acciaio decapato, magnelis, profili speciali in alluminio e profili in rame. Ogni materiale è selezionato in funzione della resistenza meccanica, della durabilità e delle caratteristiche estetiche o di resistenza alla corrosione.

Settori di applicazione dei profili metallici su misura

I nostri profili in acciaio a disegno e profilati in alluminio su misura trovano applicazione in numerosi ambiti: edilizia e prefabbricati, arredamento e cucine, serramenti, box doccia, illuminazione, parapetti in vetro, facciate ventilate, strutture fotovoltaiche, automazione industriale, carrelli elevatori, agricoltura, serre, recinzioni e impianti elettrici. La personalizzazione consente di rispondere efficacemente anche ai progetti più esigenti, garantendo funzionalità, robustezza e design.